Features & Benefits:

– Same Great Quality as the Type 1.DOT

– Designed for areas with severe conditions.

– Meet or Exceed all DOT specifications and Requirements.

– Ideal for SWPPP and as Stormwater BMP’s.

– Made in the USA

Fabric: 18oz. nominal PVC coated polyester

Base Fabric (100% Polyester) – 1000D x 1000D / 9 x 9

Weight (FS-191-5041) – 18oz/yard²

Tensile Strength, Grab (ASTM 4632) – 325 lbs x 310 lbs

Tear Strength, Tongue (ASTM 2261) – 55 lbs x 45 lbs

Elongation (ASTM 4632) – 21% x 21%

Adhesion Strength (ASTM 751) – 17 x 17 lbs/inch

Abrasion Resistance (ASTM 4833) – 325 cycles

Hydrostatic Resistance (ASTM 751) – At least 660 lbs/inch²

UV Resistance (Weather-O-Meter) – Not excessive fading after 1000 HRS

Cold Crack Resistance (ASTM 2136) – -40⁰ F

High Temperature Resistance (ASTM 2136) – 180⁰ F (Does not Block)

Flame Resistance – Pass

Special Treatment(s) – Anti Mildew

All seams heat sealed

5/8” diameter poly rope reinforced vertical edges

#5 brass grommets

5/16” galvanized steel 7×19 load cable with PVC coating in top, 10,000 lb. break strength

5/16″ galvanized chain ballast

Aluminum stress plates at cable and chain terminations

EPS flotation foam: 8” x 8” (Standard. Increases to 10” x 10” and 12” x 12” — based on curtain depth),

26.7 lb./ft. buoyancy in fresh water and 28.4 lb./ft. buoyancy in saltwater

Turbidity Barriers are a BMP designed to restrict the flow of sediment-laden storm water runoff from a construction site, to keep it contained in a limited area, and allow the sediment to settle out before being carried into adjacent or joining watercourses. TOUGH GUY® Turbidity Barriers are manufactured by AER-FLO, Inc., the world’s largest producer of these critical devices.

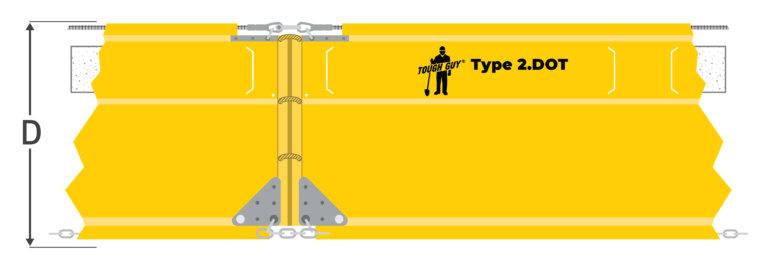

This is the workhorse of the TOUGH GUY® barrier line. Each Barrier comes supplied with a top load cable and special stress plates for reinforcing the corners and is designed to handle more severe

conditions. It is recommended for lakes, streams, inter-coastal and tidal areas where current

velocities up to five feet per second are expected.

The anchorage and installation must be designed to meet the site conditions. Contact Aer-Flo or a qualified engineer for assistance when extraordinary site conditions are encountered. Barrier sections are connected by rope lacing or nylon ties and supplied separately.

Customers also purchased