Features & Benefits:

– Quick and easy to deploy

– Widely used and accepted in most local areas

– Meet or Exceed all DOT specifications and Requirements.

– Ideal for SWPPP and as Stormwater BMP’s.

– Made in the USA

Fabric: 18oz. nominal PVC coated polyester

Base Fabric (100% Polyester) – 1000D x 1000D / 9 x 9

Weight (FS-191-5041) – 18oz/yard²

Tensile Strength, Grab (ASTM 4632) – 325 lbs x 310 lbs

Tear Strength, Tongue (ASTM 2261) – 55 lbs x 45 lbs

Elongation (ASTM 4632) – 21% x 21%

Adhesion Strength (ASTM 751) – 17 x 17 lbs/inch

Abrasion Resistance (ASTM 4833) – 325 cycles

Hydrostatic Resistance (ASTM 751) – At least 660 lbs/inch²

UV Resistance (Weather-O-Meter) – Not excessive fading after 1000 HRS

Cold Crack Resistance (ASTM 2136) – -40⁰ F

High Temperature Resistance (ASTM 2136) – 180⁰ F (Does not Block)

Flame Resistance – Pass

Special Treatment(s) – Anti Mildew

All seam heat sealed

5/8” diameter poly rope reinforced vertical edges

#4 brass grommets

1/4″ galvanized chain ballast

EPS flotation foam: 6” x 6”, 13.5 lb./ft. buoyancy in fresh water and 14.4 lb./ft. buoyancy in saltwater

– Environmentally Sensitive Area Protection

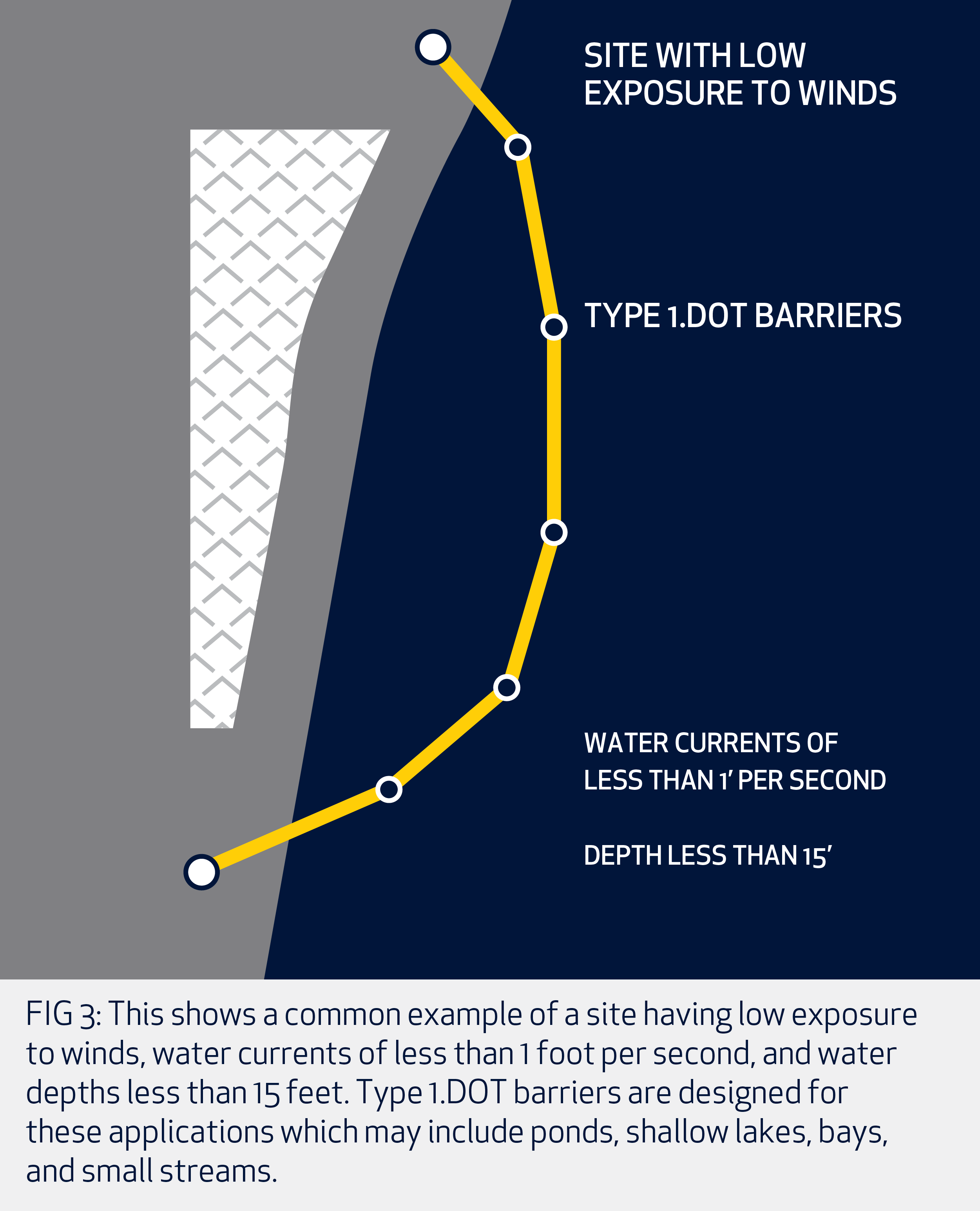

– Protected areas with light wind and water velocities of 1 ft/sec

– For ponds, shallow lakes, small streams and marshes.

– Enhance current Perimeter Sediment Pollution Control Measures

Turbidity Barriers are a BMP designed to restrict the flow of sediment-laden storm water runoff from a construction site, to keep it contained in a limited area, and allow the sediment to settle out before being carried into adjacent or joining watercourses. TOUGH GUY® Turbidity Barriers are manufactured by AER-FLO, Inc., the world’s largest producer of these critical devices.

The most commonly used turbidity barrier, this floating curtain is used in protected areas where current velocities are less than 1 feet per second. Typically sold in units 5′ x 50′. This type of site may include ponds, shallow lakes, small streams and marshes. Anchorage consisting of stakes or concrete blocks may be required to keep the barrier in its position. Barrier sections can be connected using rope lacing or nylon zip ties, which are furnished separately.

Customers also purchased